Ts'ebetso ea ho Hloekisa Oli e jeoang: Metsi a Degumming

Tlhaloso ea Sehlahisoa

Ts'ebetso ea degumming setsing sa ho hloekisa oli ke ho tlosa litšila tsa marenene ka har'a oli e tala ka mekhoa ea 'mele kapa ea lik'hemik'hale,' me ke mohato oa pele ts'ebetsong ea tlhoekiso / tlhoekiso ea oli.Kamora ho hatelloa ka sekoti le ho ntša solvent ho tsoa lipeong tsa oli, oli e tala e na le li-triglycerides le li-non-triglyceride tse 'maloa.Sebopeho se seng sa triglyceride se kenyeletsang phospholipids, liprotheine, phlegmatic le tsoekere li ne li tla itšoara ka triglycerides ho etsa colloid, e tsejoang e le litšila tsa marinini.

Litšila tsa marenene ha li ame feela botsitso ba oli empa hape li ama phello ea ts'ebetso ea ho hloekisa oli le ts'ebetso e tebileng.Ka mohlala, oli e sa hloekisoang e bonolo ho etsa oli e entsoeng ka emulsified ka mokhoa oa ho hloekisa alkaline, kahoo e eketsa bothata ba ts'ebetso, tahlehelo ea ho hloekisa oli, le tšebeliso ea lisebelisoa tse thusang;ts'ebetsong ea decolorization, oli e se nang degummed e tla eketsa ts'ebeliso ea adsorbent le ho fokotsa ts'ebetso ea discoloring.Ka hona, ho ntša marenene hoa hlokahala e le mohato oa pele tšebetsong ea ho hloekisa oli pele ho hloekisoa ha oli, ho ntšoa ha 'mala oa oli, le ho ntša monko oa oli.

Mekhoa e ikhethileng ea ho hloekisa e kenyelletsa hydrated degumming(metsi a degumming), acid refining degumming, mokhoa oa ho hloekisa alkali, mokhoa oa adsorption, electropolymerization le mokhoa oa ho futhumatsa polymerization.Ts'ebetsong ea ho hloekisa oli e jeoang, mokhoa o sebelisoang ka ho fetisisa ke hydrated degumming, e ka ntšang phospholipids ea hydratable le phospholipids e seng ea hydrate, ha phospholipids e setseng e se nang hydrate e hloka ho tlosoa ka acid refining degumming.

1. Molao-motheo o sebetsang oa degumming ea hydrated (ho hloekisa metsi)

Oli e sa tsoakoang e tsoang ts'ebetsong ea mokelikeli e na le likarolo tse qhibilihang ka metsing, haholo-holo tse nang le phospholipids, tse hlokang ho tlosoa oli ho etsa hore ho be le pula e fokolang le ho tsitsa nakong ea lipalangoang tsa oli le polokelo ea nako e telele.Litšila tsa marinini joalo ka phospholipids li na le sebopeho sa hydrophilic.Pele ho tsohle, o ka hlohlelletsa le ho eketsa tekanyo e itseng ea metsi a chesang kapa tharollo ea metsi a electrolyte joalo ka letsoai le asiti ea phosphoric ho oli e tala e chesang.Ka mor'a nako e itseng ea karabelo, litšila tsa marinini li ne li tla koaheloa, li kokobele le ho ntšoa oli.Ts'ebetsong ea hydrated degumming, litšila haholo-holo ke phospholipid, hammoho le liprotheine tse 'maloa, glyceryl diglyceride, le mucilage.Ho feta moo, marenene a nkiloeng a ka fetoloa lecithin bakeng sa lijo, lijo tsa liphoofolo kapa bakeng sa ts'ebeliso ea tekheniki.

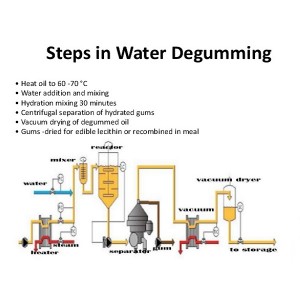

2. Mokhoa oa ho tlosa metsi ka metsi (ho hloekisa metsi)

Ts'ebetso ea degumming ea metsi e kenyelletsa ho eketsa metsi ho oli e tala, ho kenya metsi ka likarolo tse qhibilihang ka metsing, ebe o tlosa boholo ba tsona ka karohano ea centrifugal.Karolo e khanyang ka mor'a karohano ea centrifugal ke oli e sa hloekang ea degummed, 'me karolo e boima ka mor'a ho arohana ha centrifugal ke motsoako oa metsi, likarolo tse qhibilihang ka metsing le oli e kenngoeng, hammoho e bitsoa "marenene".Oli e sa tsoakoang ea degumme e omisitsoe ebe e pholile pele e romeloa polokelong.Marenene a khutlisetsoa lijong.

Setsing sa ho hloekisa oli, mochini o hloekisang hydrate o ka sebetsoa hammoho le mochini o hloekisang oli, mochini oa decolorization le mochini o tlotsang monko, 'me mechini ena ke sebopeho sa mohala oa tlhahiso o hloekisang oli.Mohala oa tlhoekiso o arotsoe ka mofuta oa nakoana, mofuta o tsoelang pele, le mofuta o tsoelang pele ka botlalo.Moreki o ne a ka khetha mofuta ho latela matla a bona a tlhahiso a hlokahalang: fektheri e nang le matla a tlhahiso ea 1-10t ka letsatsi e loketse ho sebelisa lisebelisoa tsa mofuta oa nakoana, fektheri ea 20-50t ka letsatsi e loketse ho sebelisa lisebelisoa tsa mofuta o tsoelang pele, ho hlahisa. ho feta 50t ka letsatsi ho loketse ho sebelisa lisebelisoa tsa mofuta o tsoelang pele.Mofuta o sebelisoang haholo ke mohala oa tlhahiso ea hydrated degumming ea nakoana.

Tekheniki Parameter

Lintlha tse ka sehloohong tsa Hydrated degumming (ho ntša metsi)

3.1 Bophahamo ba metsi a ekelitsoeng

(1) Phello ea metsi a ekelitsoeng ho flocculation: Metsi a lekaneng a ka etsa sebopeho se tsitsitseng sa liposome tse ngata.Metsi a sa lekaneng a tla lebisa ho hydration e sa fellang le ho phalla ho hobe ha colloidal;Metsi a feteletseng a atisa ho theha emulsification ea oli ea metsi, eo ho leng thata ho arola litšila ho tloha ho oli.

(2) Kamano lipakeng tsa metsi a ekelitsoeng (W) le bokahare ba glum (G) mochesong o fapaneng oa ts'ebetso:

| mocheso o tlase oa hydration (20 ~ 30 ℃) | W=(0.5~1)G |

| mocheso o mahareng (60 ~ 65 ℃) | W=(2~3)G |

| mocheso o phahameng oa metsi (85 ~ 95 ℃) | W=(3~3.5)G |

(3) Teko ea mohlala: Palo e nepahetseng ea metsi a ekelitsoeng e ka khethoa ka tlhahlobo ea mohlala.

3.2 Mocheso oa ho sebetsa

Mocheso oa ts'ebetso ka kakaretso o lumellana le mocheso o boima (bakeng sa ho phalla hantle, mocheso oa ts'ebetso o ka ba o phahameng hanyenyane ho feta mocheso o boima).'Me mocheso oa ts'ebetso o tla ama palo ea metsi a ekelitsoeng ha mocheso o phahame, metsi a mangata, ho seng joalo, a nyenyane.

3.3 Matla a motsoako oa hydration le nako ea ho arabela

(1) Inhomogeneous hydration: Gum flocculation ke karabelo e fapaneng ho sebopeho sa tšebelisano.E le hore ho thehoe boemo bo tsitsitseng ba emulsion ea oli-metsi, ho kopanya mochine oa motsoako ho ka etsa hore marotholi a qhalane ka ho feletseng, ho kopanya mechine ho hloka ho matlafatsoa haholo-holo ha palo ea metsi a ekelitsoeng e le khōlō 'me mocheso o le tlaase.

(2) Matla a ho kopanya hydration: Ha o kopanya oli le metsi, lebelo le tsosang ke 60 r / min.Nakong ea ho hlahisa flocculation, lebelo le tsosang ke 30 r / min.Nako ea karabelo ea motsoako oa hydration ke metsotso e ka bang 30.

3.4 Li-electrolyte

(1) Mefuta e fapaneng ea li-electrolyte: Letsoai, alum, silicate ea sodium, phosphoric acid, citric acid le tharollo ea sodium hydroxide e hlapollang.

(2) Mosebetsi o ka sehloohong oa electrolyte:

a.Li-electrolyte li ka fokotsa tefiso ea motlakase ea likaroloana tsa colloidal le ho khothalletsa likaroloana tsa colloidal ho sedimentate.

b.Ho fetolela li-phospholipids tse se nang hydrated ho li-phospholipids tse hydrated.

c.Alum: thuso ea flocculant.Alum e khona ho monya mebala ka har'a oli.

d.Ho chelate ka li-ion tsa tšepe le ho li tlosa.

e.Ho khothaletsa flocculation ea colloidal haufi le ho fokotsa litaba tsa oli ea li-flocs.

3.5 Lintlha tse ling

1

(2) mocheso oa metsi a ekelitsoeng: Ha ho kenngoa metsi, mocheso oa ho eketsa metsi o lokela ho lekana kapa o phahame hanyenyane ho feta mocheso oa oli.

(3) Boleng ba metsi bo ekelitsoeng

(4) Ho tsitsa ha ts'ebetso

Ka kakaretso, litekanyo tsa tekheniki tsa ts'ebetso ea degumming li khethoa ho latela boleng ba oli, 'me litekanyetso tsa oli tse fapaneng ts'ebetsong ea degumming li fapane.Haeba u na le thahasello ea ho hloekisa oli, ka kopo ikopanye le rona ka lipotso kapa maikutlo a hau.Re tla hlophisa baenjiniere ba rona ba litsebi ho etsa mohala o loketseng oa oli o nang le lisebelisoa tsa ho hloekisa oli tse tsamaellanang le uena.